Our Businesses

- Home

- Our Businesses

- Research and Development

Research and Development

We accept your requests for various tests, in addition to Research and Development of our products and services.

Technical R&D Lab.

Railway is advancing day after day in a safer, more comfortable, more people- and environment-friendly manner. In order to change a wide range of needs for railway into reliable technologies, Technical R&D Lab. proactively challenges practical use of a two-step gradient pressure-welded crossing and turnouts with steel sleepers, development of movable crossings, and LED-based crossing indicators, as well as Goldsummit welding technique in concerted efforts with our customers.

-

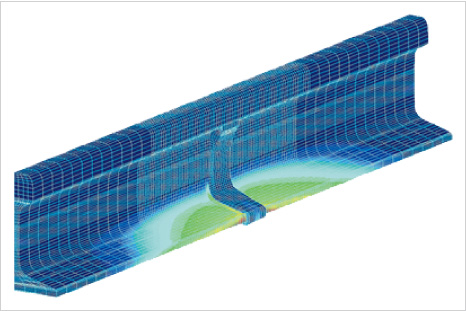

Stress Analysis of Goldsummit Weld Zone by Finite Element Method

-

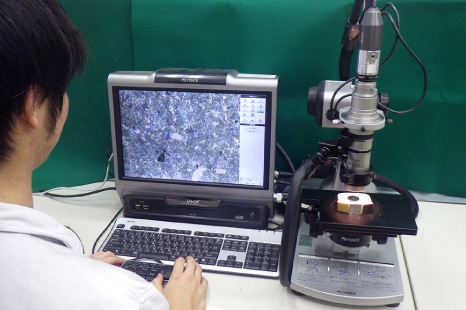

Micro analysis of rails using electron microscope

-

Stress Measurement in Fatigue Testing machine

-

Development of New Movable Nose Crossing

-

Three-Rail Turnout Switching Force Test

-

Measurement and Testing

- Stress analysis of rail weld zone

- Static bending test of rail weld zone

- Measurement of throwing force at tongue rail and movable rail

- Measurement of stress by the strain gauge

- Measurement of hardness (Shore, Brinell and Vickers)

-

Development and Improvement

- Movable wing rail crossing

- Movable nose crossing

- New-type movable nose crossing

- Injection moulding of insulation plate of steel sleeper

-

Field survey

- On-site observation of turnout

- Switching force, wheel load, lateral force, various stress measurements

- Non-destructive inspection of welding joint