Our Businesses

- Home

- Our Businesses

- Rail welding

- Brass brazing and finish inspection

Brass brazing and finish inspection

We perform the following work in addition to the main welding methods:

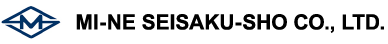

Conductivity enhanced brazing

A brazing method is applied to rails with low vehicle passing frequency in order to enhance the conductivity of a rail signal current. To groove the running surface of the rail and braze with oxygen and an acetylene gas flame.

Finish inspection

Finish inspection of rail weld zones is important work to confirm their quality.

Properly finished weld zones result in a comfortable train ride and reduce noise.

Our qualified engineers conduct highly reliable inspection to satisfy customers' requests.

-

Running surface finish inspection

The finish accuracy of the running surface of a rail is inspected in unit of 0.1 mm.

This inspection is performed for the entire rail welding. -

Magnetic particle inspection

Fine surface defects are inspected by magnetizing the zone to be welded and making magnetic particles adhere to it. This inspection is performed for gas pressure welding and flash butt welding.

-

Penetrant inspection

Fine surface defects are inspected by applying penetrant to the welding zone, wiping away the surface, and spray developing powder. This inspection is performed for Goldsummit welding and enclosed arc welding.

-

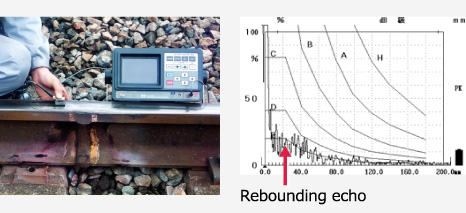

Ultrasonic inspection

Defects generated inside a rail are inspected by emitting ultrasonic waves and investigating the rebounding echo. This inspection is performed for Goldsummit welding and enclosed arc welding.